Yaki-Sugi exterior walls are so cool

But I have a lot of questions…

Is it really durable enough?

Can it be used in the city in Japan?

An architect who has experience using Yaki-Sugi will explain in detail.

Contents

- Production method

- Advantages and Disadvantages

- Reference price

- Can it be used in urban areas in Japan?

- Share of the detached housing market in Japan

- Examples of non-residential use

- Yaki-Sugi spread around the world through SNS

- summary

Production method

Yaki-Sugi can be produced in two ways: by hand (hand-burning) or in a factory with a burner (burner-burning).

Hand-burning

Hand-burning is a traditional method handed down from generation to generation on the islands of the Seto Inland Sea.

Three cedar planks are placed vertically in a triangular cylindrical shape and ignited using rolled up newspaper.

The surface of the boards can be thoroughly burned to form a deep carbon layer.

This deep carbon layer is the reason for the durability of the wood, which is said to last 60 to 70 years.

Burner-burning

Burner burning is a method in which cedar boards are placed on a conveyor belt at a factory and then fired using a special machine.

It is suitable for mass production, but the carbon layer on the surface is thinner than that of hand-burning, and is said to be slightly less durable.

If durability is important to you, choose Hand-burning ones

Advantages and Disadvantages

Advantages

✅As a natural material, it does not lose its aesthetic appeal over time.

✅Compatible with a wide range of designs, from old houses to modern architecture

✅Long service life due to the carbon layer coating on the surface

✅Not a manufacturer’s product, so it will never be discontinued

✅The individual boards are lightweight, making future replacement work relatively easy.

Disadvantages

✅Charcoal will stick and stain when touched

✅Because it is solid wood, deformation and gaps may occur.

✅Surface may peel off when objects hit it in typhoons, etc.

✅Basically made-to-order, so delivery takes time

As a countermeasure against demerits, narrow the nail spacing during installation and firmly fix the nails to the base furring strips to prevent deformation and gaps from occurring.

In addition, if the surface is delaminated, it should be partially painted or reupholstered.

Reference price

These are reference prices as of November 2018 for Yaki-Sugi used in a house in Miyagi Prefecture, Japan.

Mori Zaimokuten (Ushimado-machi, Setouchi City, Okayama Prefecture) was employed.

We were able to reduce overhead costs by ordering directly from the lumber dealer.

Yaki-Sugi board 5,700 yen/tsubo + consumption tax

Meiban (wooden board): 185 yen/pc + consumption tax

Shipping cost 129,600 yen (Okayama to Miyagi Prefecture, consumption tax included)

If you can do DIY burning, you can save even more money

Can it be used within an urban area (quasi-fire prevention area, Article 22 area of the law) in Japan?

Even in urban areas (quasi-fire prevention zones and Article 22 zones) in Japan, Yaki-Sugi can be used if the walls are “fireproof construction certified”.

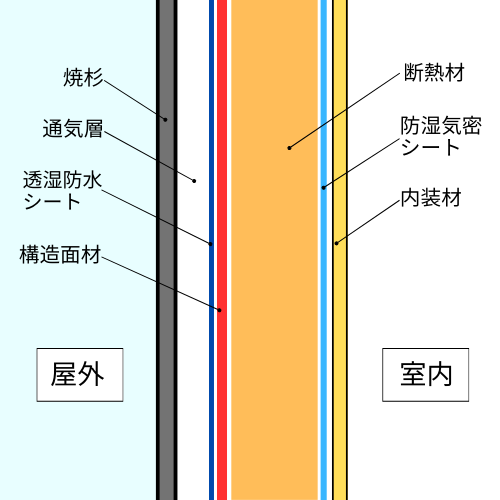

Fireproof construction certification is explained with figures.

Thus, it is possible to form a “fireproof construction-certified” exterior wall by using yaki-cedar as the outermost decorative material, affixing the designated structural facing material (such as Yoshino Gypsum “Tiger EX Board”) inside it, and filling it with heat insulating material or the like.

In terms of performance other than fireproofing, waterproofing is ensured by moisture-permeable waterproof sheets, earthquake resistance by structural facing materials, heat insulation by high-performance glass wool, and airtightness by moisture-proof airtight sheets, respectively, to form high-performance exterior walls (high heat insulation and high airtightness).

By the above,

quasi-fire prevention area

The total area of the building must be less than 500㎡ and either a single-story or two-story building.

Article 22 area of the law (area where there is a fear of fire spreading)

As in semi-fire zones, it can be used by making the wall a certified fireproof construction.

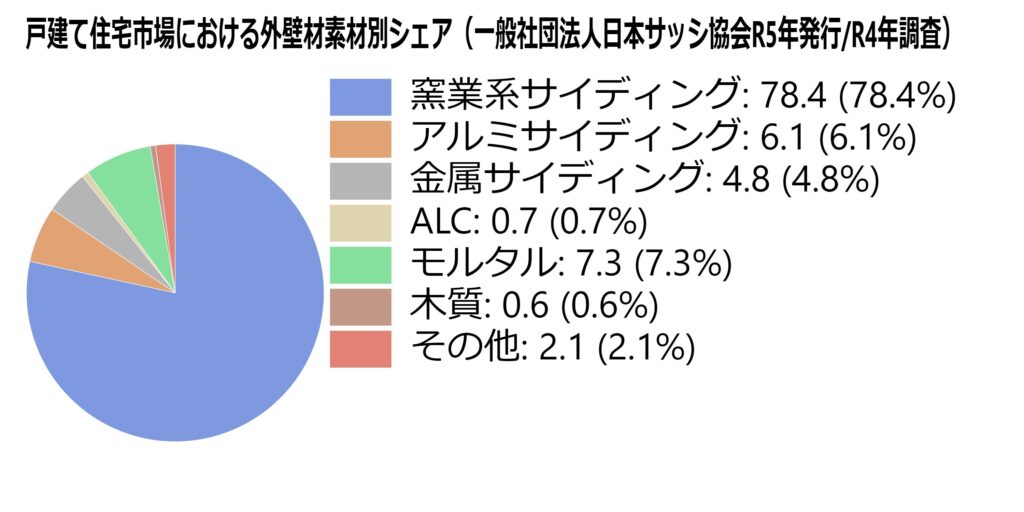

Share of the detached housing market in Japan

According to the Japan Sash Association’s Survey on the Use of Building Materials for Housing in 2023, the share of wood exterior walls in detached houses in Japan is 0.6% of the total.

Since Yaki-Sugi is a type of wood exterior wall, we can estimate that only 3 to 6 out of every 1,000 houses have Yaki-Sugi, at most.

This indicates that the use of yaki-cedar is not as widespread as it appears on the Internet and in magazines.

We think the reason for this is that housing suppliers have not been very proactive in proposing wood-based wall products because of their inability to handle them.

Examples of non-residential use

Yaki-Sugi exterior walls can be used in a variety of designs, from traditional Japanese-style homes to contemporary architecture.

The following are typical examples.

Ramune Onsenkan Taketa City, Oita Prefecture

Juzo Itami Memorial Museum Matsuyama City, Ehime Prefecture

COMICO ART HOUSE YUFUIN Yufu City, Oita Prefecture

Takabe Community Center Chino City, Nagano Prefecture

Kodomari Fuji Fujimi Town, Nagano Prefecture

Architect and architectural historian Terunobu Fujimori was the first architect to use Yaki-Sugi (2005) and made it known to the public.

Yaki-Sugi spread around the world through Social Media

Yaki-Sugi, including the manufacturing process, can be the “instagenic” material.

And it can be made anywhere in the world, as long as you have enough wood for the boards, paper for fuel, and a large space.

With this background, it became one of the buzz contents on Social Medias.

Yaki-Sugi has attracted attention from popular overseas DIY YouTubers, and you can watch many videos of yakisugi from around the world by searching for words such as “Yakisugi” and “Sho Sugi Ban.

The responses in the comment sections of these videos also show the high level of interest from overseas.

summary

Hand-burned cedar with a thick carbon layer is recommended for durability.

Fix the boards firmly to the furring strips at the time of installation to prevent deformation and gaps.

If the surface is peeled off due to accidental damage, it should be partially painted or replaced.

If you want to keep costs down, buy directly from a lumber dealer (or DIY).

Can be used in urban areas (quasi-fire prevention zones and Article 22 zones).

Various designs from Japanese to modern architecture

The “Instagenic” material that has become popular around the world.

コメント